Resin 3D printing is a fascinating and rapidly evolving technology that allows you to create highly detailed and precise objects with incredible accuracy. With its ability to produce smooth surfaces, intricate designs, and high-resolution prints, resin 3D printing has gained popularity in various industries, including jewelry making, dental modeling, prototyping, and small-scale production.

In this guide, we aim to provide you with all the information you need to navigate the world of resin 3D printing confidently. Whether you are a beginner looking to explore this exciting technology or an experienced user seeking to enhance your printing skills, this guide will serve as your go-to resource.

So, let’s dive into the world of resin 3D printing and discover the endless possibilities it offers. Get ready to unlock your creativity and bring your ideas to life with resin 3D printing!

How Resin 3D Printing Works

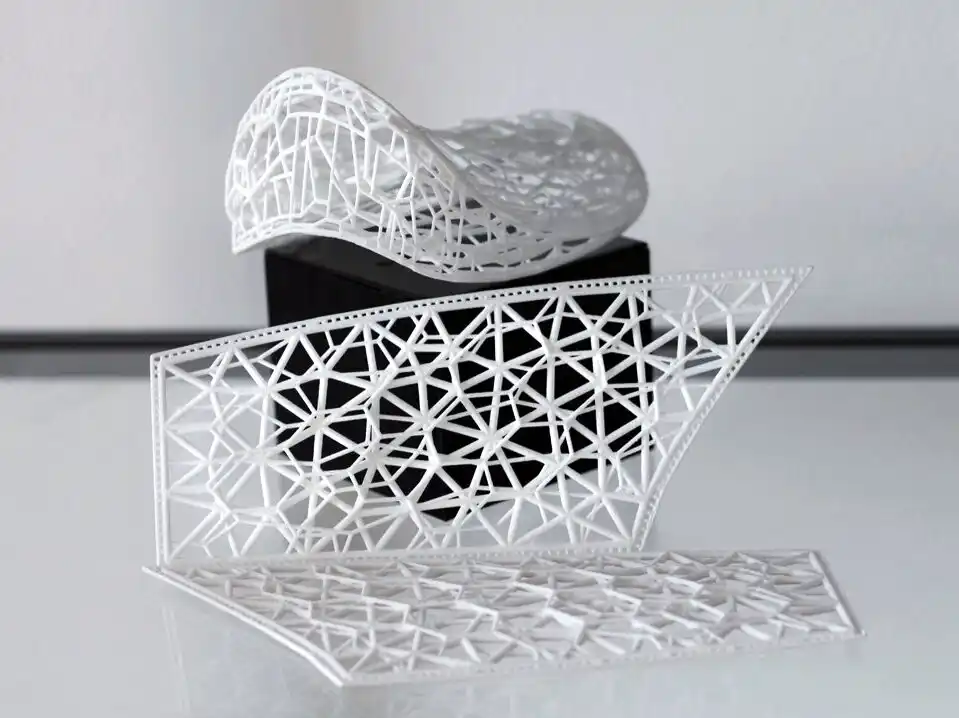

Resin 3D printing, also known as stereolithography (SLA) or digital light processing (DLP), is a fascinating additive manufacturing process that utilizes liquid photopolymer resin materials to create highly detailed and precise objects. Unlike traditional filament 3D printing, resin printing involves curing liquid resin into a solid shape layer by layer using UV light.

The process begins with a vat of liquid resin, which is then selectively cured by a light source, such as a laser or projector, according to the specific shape of the object being printed. As each layer is cured, the build platform is lowered, allowing for the next layer to be added. This layer-by-layer approach results in highly accurate and intricate prints.

One of the key advantages of resin 3D printing is its ability to produce objects with incredibly fine details and smooth surfaces. The curing process allows for the creation of complex features and high levels of accuracy. Additionally, resin printers offer a wide range of materials, including engineering-grade resins, flexible resins, and dental composite resins.

While resin 3D printing offers superior resolution and surface finish, it does come with some limitations. The printing size is often smaller compared to filament 3D printers, and the process requires extensive post-processing, including washing, curing, and sanding. It’s also important to note that resin printing can release toxic fumes during the printing process, so proper ventilation is essential.

In conclusion, resin 3D printing is a powerful technology that provides highly detailed and precise prints. Its ability to create objects with intricate features and smooth surfaces makes it ideal for applications such as jewelry, dental models, prototyping, and small-scale production items. However, it’s important to consider the limitations and post-processing requirements when deciding if resin 3D printing is the right choice for your project.

Benefits of Resin 3D Printing

Resin 3D printing offers numerous benefits that make it a popular choice for various applications. Here are some key advantages of using resin 3D printers:

High Precision and Detail

Resin printers are capable of producing parts with incredibly fine details and smooth surfaces. The layer-by-layer curing process allows for intricate designs and complex features, making it ideal for creating highly detailed models, jewelry, and dental models.

Wide Range of Materials

Resin printers can use a variety of engineering-grade resins, flexible resins, and dental composite resins. This versatility allows for the production of parts with different properties, such as flexibility, strength, and biocompatibility.

Water-Resistant Prints

Resin prints possess the quality of being resistant to water. Unlike plastics or powdered materials, photopolymers solidify when applied and continue to be water-resistant. Most photopolymers are suitable for applications requiring water tightness because they do not absorb moisture from their surroundings.

Unaffected Surface Quality

Supports barely affect the quality of the surface. Any slight overhangs can simply join to the main structure of the object during the curing process because the resin tank has resin along the entire boundary. This ensures a smooth and seamless surface finish.

Faster Printing Speed

Resin printers can produce prints at a faster rate compared to other 3D printing methods. Some resin printing technologies, such as DLP and LCD-based printing, can cure entire layers at once, resulting in quicker print times.

Higher Tensile Strength

Resin prints generally have higher tensile strength compared to filament prints. This makes them more durable and resistant to mechanical stress, making them suitable for functional parts and prototypes.

Overall, resin 3D printing offers exceptional precision, a wide range of material options, and the ability to create highly detailed and durable prints. These advantages make it a preferred choice for industries such as jewelry, dental, and prototyping.

Types of Resin 3D Printers

When it comes to resin 3D printers, there are several different types available on the market. Each type has its own unique features and advantages, allowing users to choose the one that best suits their needs. Here are some of the most common types of resin 3D printers:

Stereolithography (SLA) Printers: SLA printers use a laser or UV light to cure liquid resin into solid objects. These printers offer high resolution and accuracy, making them ideal for creating detailed and intricate models.

Digital Light Processing (DLP) Printers: DLP printers use a projector to cure the resin layer by layer. They offer fast printing speeds and high resolution, making them suitable for both small-scale and large-scale production.

LCD Printers: LCD printers use an LCD screen to selectively cure the resin. They offer a good balance between speed and resolution, making them a popular choice among hobbyists and professionals alike.

Continuous Liquid Interface Production (CLIP) Printers: CLIP printers use a combination of light and oxygen to cure the resin. They offer fast printing speeds and high resolution, making them suitable for industrial and commercial applications.

Multi-Jet Printing (MJP) Printers: MJP printers use multiple print heads to deposit photopolymer droplets onto a build platform. They offer high resolution and accuracy, making them ideal for creating detailed prototypes and models.

PolyJet Printers: PolyJet printers use inkjet technology to deposit layers of liquid photopolymer onto a build platform. They offer high resolution and the ability to print in multiple colors and materials, making them suitable for a wide range of applications.

When choosing a resin 3D printer, it is important to consider factors such as printing speed, resolution, build volume, and cost. By understanding the different types of resin 3D printers available, users can make an informed decision and find the printer that best meets their needs.

Choosing the Right Resin 3D Printer

When it comes to choosing the right resin 3D printer, there are several factors to consider. First and foremost, you need to think about your specific needs and the intended use of the printer. Are you a hobbyist looking to create small, intricate models, or do you have larger projects in mind? Understanding your requirements will help narrow down your options.

Another important consideration is the printer’s build size. If you plan on printing larger objects, you’ll need a printer with a larger build volume. However, keep in mind that larger printers can be more expensive and may require more resin, increasing running costs. It’s essential to strike a balance between your project requirements and your budget.

Print quality is another crucial factor to consider. Resin printers are known for their high-resolution prints and smooth surface finishes. However, different printers may offer varying levels of print quality, so it’s important to research and read reviews to ensure you choose a printer that meets your expectations.

Additionally, think about the printer’s user interface (UI) and ease of use. A printer with a user-friendly touchscreen interface can make your printing experience more enjoyable and efficient. Consider the connectivity options as well, such as Wi-Fi or USB, and choose a printer that suits your workflow.

Lastly, don’t forget about safety features. Look for printers that have automatic nozzle cooling and other safety measures to prevent accidents and ensure a safe printing environment.

By carefully considering these factors and doing thorough research, you can choose the right resin 3D printer that meets your specific needs and delivers high-quality prints.

Best Practices for Resin 3D Printing

When it comes to resin 3D printing, there are several best practices that can help you achieve the best results. These practices will not only improve the quality of your prints but also ensure a smoother printing process overall. Here are some key tips to keep in mind:

Calibrate your printer

Proper calibration is essential for achieving accurate and precise prints. Make sure to calibrate the build plate, resin level, and exposure settings according to the manufacturer’s guidelines.

Choose the right resin

Different resins have different properties and are suitable for specific applications. Consider factors such as strength, flexibility, and color when selecting a resin for your project.

Handle resin with care

Resin can be toxic and messy, so it’s important to take proper safety precautions. Wear gloves, goggles, and a mask when handling resin, and ensure proper ventilation in your workspace.

Clean and maintain your printer

Regularly clean the resin vat, build plate, and other components of your printer to prevent contamination and ensure optimal performance. Follow the manufacturer’s instructions for cleaning and maintenance.

Use supports effectively

Supports are necessary for printing objects with overhangs or complex geometries. Properly orient your model and add supports where needed to ensure successful printing and easy removal of supports post-printing.

Post-processing and curing

After printing, remove the print from the build plate and clean it thoroughly to remove any excess resin. Then, cure the print using UV light to fully harden the resin and enhance its strength.

Experiment and iterate

Resin 3D printing can involve a bit of trial and error. Don’t be afraid to experiment with different settings, orientations, and resin types to achieve the desired results. Learn from each print and make adjustments as needed.

By following these best practices, you can optimize your resin 3D printing process and achieve high-quality prints with ease. Remember to always refer to the manufacturer’s guidelines and seek advice from the resin 3D printing community for additional tips and insights. Happy printing!

Post-Processing and Finishing Techniques

Once you have completed a print with your resin 3D printer, there are a few post-processing and finishing techniques you can use to enhance the final result. These techniques will help you achieve a smoother surface finish, remove any support structures, and add additional details or coatings to your print.

One important step in post-processing is cleaning your print. After removing it from the printer, you should rinse it in isopropyl alcohol to remove any uncured resin. This will ensure that your print is clean and ready for further processing.

Next, you may need to remove any support structures that were printed along with your object. Depending on the complexity of the design, this can be a simple task or require more careful removal. Use pliers or a similar tool to gently break away the supports, taking care not to damage the main structure.

To achieve a smoother surface finish, you can sand your print using fine-grit sandpaper. This will help remove any visible layer lines and create a more polished appearance. Additionally, you can use a resin-specific primer or filler to further smooth the surface and prepare it for painting or other finishing techniques.

If you want to add additional details or coatings to your print, you can consider painting or applying a protective finish. Acrylic paints work well on resin prints, allowing you to add color and detail to your object. Additionally, you can apply a clear coat or varnish to protect the print and give it a glossy finish.

Remember to follow safety precautions when working with resin and post-processing materials. Wear gloves and work in a well-ventilated area to avoid any potential health risks.

By utilizing these post-processing and finishing techniques, you can take your resin 3D prints to the next level, achieving a professional and polished result. Experiment with different methods to find the best approach for your specific project and enjoy the impressive capabilities of resin 3D printing.