The world of manufacturing is witnessing a paradigm shift with the advent of advanced technologies like 3D printing. Among the various 3D printing technologies, Digital Light Processing (DLP) is making significant inroads, revolutionizing how products are designed, prototyped, and produced. In this article, we’ll delve into the intricacies of DLP 3D printing and explore its transformative impact on the manufacturing industry.

The Basics of DLP 3D Printing Technology

What is DLP 3D Printing?

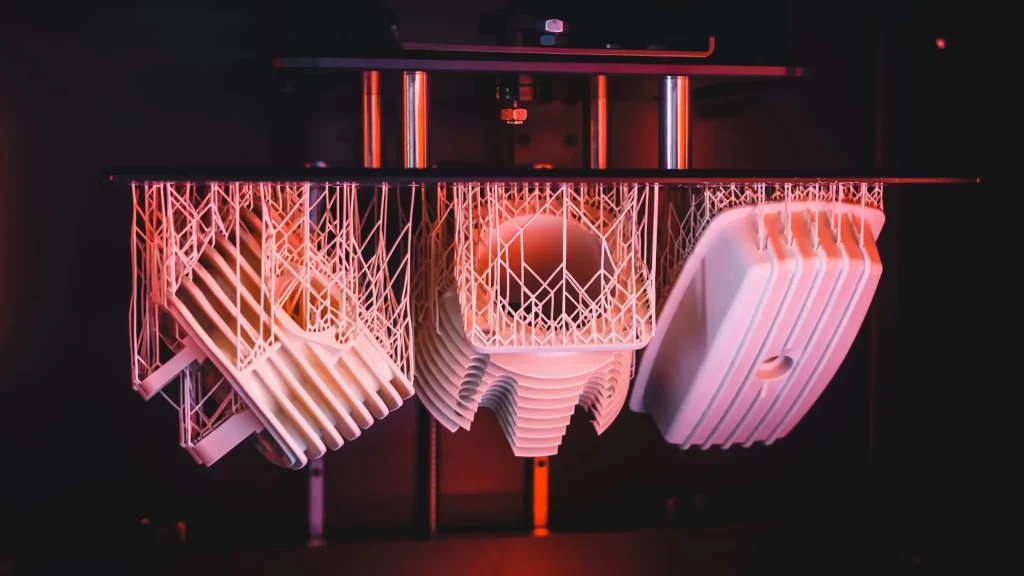

DLP 3D printing is a form of additive manufacturing that uses a digital light projector to cure photopolymer resins, layer by layer, to create intricate and highly detailed physical objects. This technology is known for its precision and speed, making it a preferred choice for a variety of applications.

The Process

DLP printers employ a light source to project images of each layer onto a vat of photosensitive resin. The resin hardens upon exposure to the light, and the build platform incrementally moves to allow the next layer to be cured, building the object from the bottom up.

Applications of DLP in Manufacturing

Precision and Customization

The precision of DLP 3D printing allows for the creation of parts with intricate details, which is ideal for custom manufacturing and applications where detail is paramount.

Speed of Production

DLP’s speed is beneficial for rapid prototyping, reducing the time from design to prototype and accelerating the product development cycle.

Cost-Effectiveness

Reduced waste, lower energy consumption, and the ability to produce parts on-demand make DLP a cost-effective manufacturing solution.

DLP’s Impact on Various Industries

Healthcare

DLP technology is used to create customized dental implants, hearing aids, and prosthetics, tailored to individual patient needs.

Aerospace

The aerospace industry benefits from DLP’s ability to produce lightweight, complex components that withstand extreme conditions.

Automotive

Automakers leverage DLP for both prototyping and production of components, reducing weight and increasing fuel efficiency.

The Future of Manufacturing with DLP

Innovations on the Horizon

Advancements in DLP technology continue to expand its capabilities, promising even greater speed, precision, and material versatility.

Sustainability and Environmental Impact

DLP printing contributes to sustainability through efficient material usage and the potential for recycling resins.

The Role of DLP in Mass Production

As DLP technology evolves, its role in mass production is set to grow, offering a viable alternative to traditional manufacturing methods.

Challenges and Considerations

Technical Challenges

Despite its advantages, DLP faces technical challenges, such as ensuring consistent light exposure and managing heat dissipation.

Material Limitations

The range of materials suitable for DLP is currently limited, but ongoing research is expanding the options available.

Market Adoption

The adoption of DLP in the manufacturing sector is influenced by factors like cost, awareness, and the availability of skilled operators.

Conclusion

DLP 3D printing is a game-changer for the manufacturing industry, offering unparalleled precision, speed, and cost-efficiency. As the technology continues to mature, its influence is set to expand, paving the way for innovative manufacturing processes.