Imagine meticulously crafting a complex design, only to wonder if the intricate details you’ve envisioned can truly come to life. Navigating the labyrinth of innovation, many product developers face this pivotal moment where an idea teeters between vision and reality. This is where the magic of Stereolithography (SLA) 3D printing illuminates the path. With its unparalleled precision and finish, SLA technology has become a beacon in the realm of rapid prototyping, transforming abstract concepts into tangible models with an almost sculptor’s finesse.

SLA 3D printing stands out in the digital fabrication universe as a technique renowned for its excellent surface finish and high level of detail. It has empowered designers and engineers to transcend traditional manufacturing shackles, thrusting them forward in a race against time to innovate, iterate, and introduce new products to the market with unprecedented speed. The term ‘rapid’ in prototyping is a solemn pledge, one that SLA 3D printing delivers with each layer it cures with ultraviolet light.

But how did we arrive at this juncture where beams of light sculpt resins into prototypes overnight? And more importantly, in what ways does SLA 3D printing provide a competitive edge to designers and businesses alike?

As we delve deeper into the intricacies of SLA 3D printing, this article will dissect its significant contribution to the fast-paced world of product development. From the symphony of light that hardens liquid resin into solid form to the smooth contours that emerge from the printer bed, you’ll come to understand not only how SLA 3D printing operates but also why it’s considered indispensable for rapid prototyping.

Join us on this explorative journey as we uncover the layers of this revolutionary technology. Together, we will examine its mechanisms, marvel at its applications, and critically evaluate its potentials and limitations, setting forth a comprehensive narrative of how an idea leaps from the drawing board and lands into our hands, all thanks to the extraordinary capabilities of SLA 3D printing.

Understanding SLA 3D Printing: The Technology Behind Rapid Innovation

As the cornerstone of modern design and manufacturing, SLA 3D printing has revolutionized how we approach the creation of new products. At its core, Stereolithography—or SLA—is a symphony of light and chemistry that brings even the most intricate designs to life with astonishing detail. Let’s dive into the intricacies and unravel the threads that make SLA not just a tool, but a craftsman of the digital age.

The Genesis of Precision: What Is SLA 3D Printing?

SLA 3D printing is akin to a silent orchestra playing in the heart of a machine; a complex process where every move is calibrated, every note resonates with purpose. Here’s how the music unfolds:

- Laser and Projector: The primary conductors, directing the flow of movements with precision.

- Resin: A pool of possibilities, a liquid medium that awaits transformation.

- Building Platform: The stage where raw materials meet destiny to become a masterpiece.

- Recoating Blade: The unassuming artist, sweeping across the stage to set the scene for the next layer of innovation.

How Does SLA 3D Printing Work?

- Preparing the 3D Model: It begins with an idea, converted into digital blueprints, ready to be birthed into reality.

- Slicing the Model: Like a meticulous butcher, the model is sliced into thin layers, each a cross-section of the future object.

- Layer-by-Layer Curing: A laser dances across the resin, hardening it, as layer upon layer it ascends towards completion.

- Post-Processing: The final touches where the object sheds its supports, is polished, and steps out, ready to face the world.

A Time-Lapse of Innovation: History of SLA

From the dawn when Chuck Hull unveiled Stereolithography in 1984, SLA 3D printing has *evolved*. It’s a narrative not just of a machine, but of the quest to **transcend the borders of the imagination**:

- 1980s: The age of inception, where ideas solidify into a new form of creation.

- 1990s to 2000s: A period of proliferation, as SLA becomes the muse of industries, birthing prototypes and models.

- Today: SLA now stands as a beacon of custom manufacturing, no longer just an instrument for prototypes but a medium for final products as well.

Anatomy of an SLA 3D Printer

Peel back the layers of an SLA 3D printer, and you’ll find a trove of precision engineering:

- Light Source: The laser or projector, commanding the resin with an artist’s precision.

- Resin Tank: The chalice that holds the liquid medium, the womb of creation.

- Build Platform: The altar where substance meets vision.

- Recoating Blade: The sculptor’s knife that ensures each layer is pristine.

The Process: From Digital to Tangible

When we dissect the SLA printing process, we’re not just looking at a machine in motion; we’re witnessing a transformation:

- The Blueprint: It starts with a 3D model, a digital skeleton of the desired object.

- The Slicing: The model is dissected into thin, horizontal slices, each an architect’s dream.

- The Curing: Layer by layer, light coaxes the resin into form, building upon the skeleton.

- The Birth: The final object emerges, not just made but crafted, a testament to the harmony of technology and vision.

Nurturing the Controversial: Is SLA Printing Truly Superior?

Herein lies a contentious debate. Traditionalists may argue that SLA is overkill, a high maintenance darling of the 3D printing world. Yet, those intoxicated by its precision counter that nothing else compares. Where do we land in this dichotomy?

Pros of SLA:

- Detail like no other, a print that is not printed but born.

- A finish so smooth, it rivals the caress of a painter’s brush.

Cons of SLA:

- A diva in its complexity, demanding attention and precision.

- The resin, a material indulgent in its use, fickle in its post-processing.

In conclusion, SLA 3D printing is not just a technology; it’s a portal to a world where the only limit is the scope of one’s imagination. As every layer solidifies under the scrutinizing gaze of the laser, we don’t just see a product taking shape; we witness the future being built before our eyes.

SLA: a story, a journey, a revolution—one layer at a time.

SLA 3D Printing Materials: Crafting the Future Layer by Resin Layer

Embarking on a journey through the world of SLA 3D printing materials is like stepping into an alchemist’s lab, where each resin holds the potential to morph from liquid to a solid monument of innovation. In this arcane study, the resins are not merely substances, but characters in their own right, each possessing unique capabilities to breathe life into a creator’s vision. Let’s unveil the mysteries that these bottled potentials carry within their viscous depths.

The Cast of Resins: A Diverse Ensemble

Like actors taking the stage, various SLA resins step into the spotlight, ready to perform. Each with a role to play in the grand design of prototyping:

- Standard Resins: The all-rounders; reliable, cost-effective, versatile.

- Engineering Resins: The problem solvers; made to simulate a range of injection-molded plastics.

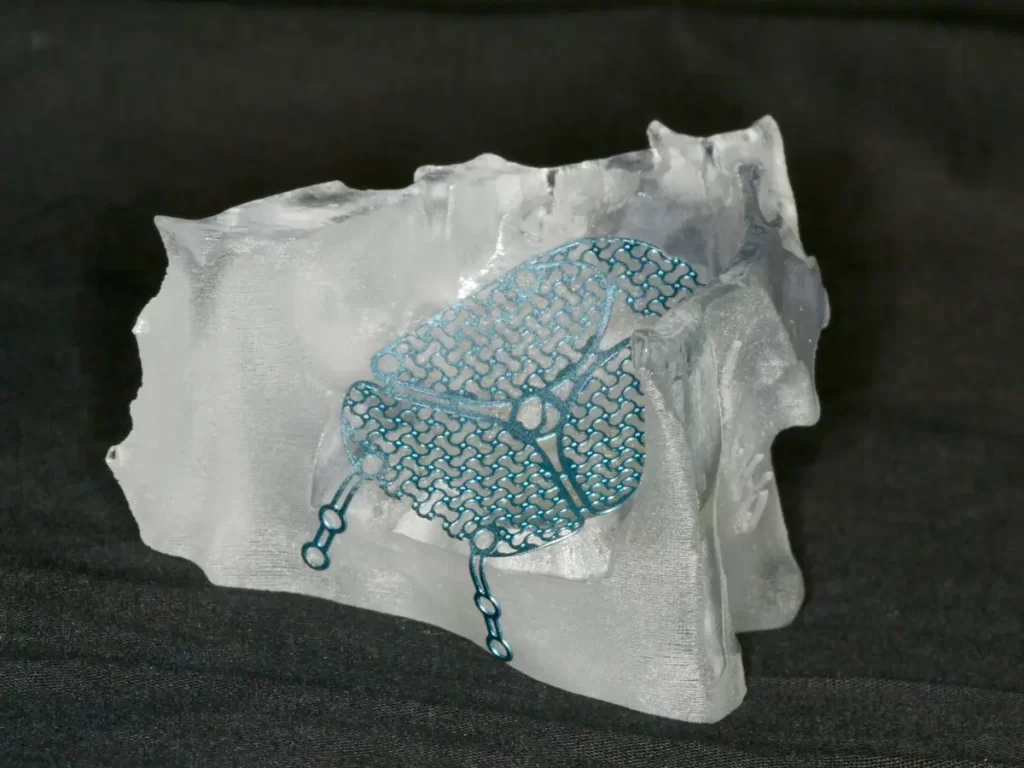

- Castable Resins: The transformers; destined to burn out, leaving behind a perfect replica in metal.

- Dental and Medical Resins: The specialists; biocompatible, designed for precision and safety in health applications.

Unmasking the Properties of SLA Resins

With each resin, we delve deeper into the essence of its existence:

- Mechanical Strength: Engineering resins flex their muscles, carrying the load where others falter.

- Temperature Resistance: Certain resins stand unyielding against the onslaught of heat, immune to warping.

- Biocompatibility: Medical-grade resins, the healers, safe in their touch, and trusted in their embrace.

The Alchemy of SLA Printing: Controversies and Considerations

And yet, beneath the surface of possibilities, there lurk the subtle issues that stir debate. The selection of materials in SLA printing is not without its controversies and considerations:

- Handling and Safety: Standard resins are user-friendly, but others demand respect with safety gear and precautions.

- Disposal and Environmental Impact: Post-processing of SLA wastes requires thoughtful consideration, committing us to the pursuit of sustainability.

- Cost Implications: While standard resins are gentler on the purse, specialty resins ask for a higher tribute for their exceptional traits.

Advantages of SLA for Rapid Prototyping

In the vibrant realm of additive manufacturing, every technology vies for the crown of efficiency and precision. Amidst this competitive banter, SLA 3D printing stands tall, boasting an array of benefits that make it an indisputable ally in rapid prototyping. Let’s unwrap these advantages that solidify SLA’s standing in the 3D printing dominion.

Precision Engineering: The Hallmark of SLA

As the needle drops in the grooves of a well-crafted vinyl, so does the laser in an SLA printer trace the fine lines of design with **exquisite accuracy**:

- High Resolution: SLA excels in capturing the minutiae, the subtleties that give a prototype its identity.

- Smooth Surface Finish: Like the serene glide of a pebble across calm waters, SLA achieves finishes that are velvety to the touch.

Complexity at No Additional Cost

In a twist of pure wizardry, SLA embraces complexity without demanding more coinage. It’s like commissioning an elaborate symphony for the price of a solo performance:

- Intricate details? SLA says, without a flinch, “the more, the merrier.”

- Internal channels, thin walls, and complex geometries are all in a day’s work for this technology.

A Material World: Versatility of Choice

SLA is the embodiment of a **Renaissance artist**, never confined to a singular medium. The breadth of materials at disposal allows an artist to paint with a broader palette:

- Functional Prototypes: With materials that mimic commercial plastics, SLA transcends mere form to test function.

- Aesthetic Models: Transparency, color, and form come together, culminating in prototypes that are a feast for the eyes.

Blink and It’s Done: Rapid Results

In the race against time, **speed is king**. SLA is not one to linger in the shadows, it steps up:

- Quick Turnaround: Prototypes emerge swiftly from their resin bath, ready for the world in mere hours.

- Less Post-Processing: With a finish that’s already refined, SLA scoffs at extensive post-production.

SLA vs. Other 3D Printing Technologies: A Comparative Examination

In the grand coliseum of 3D printing technologies, various contenders step into the arena, each brandishing their strengths and trumpeting their virtues. Among these pugilists, SLA boasts a finesse akin to a skilled fencer in a battle of brute force. But how does SLA hold up when pitted against the titans of the trade – FDM (Fused Deposition Modeling) and SLS (Selective Laser Sintering)? Let’s beckon forth the contestants and explore this clash of creations.

SLA vs. FDM: The Duel of Detail and Practicality

First to the stage is FDM, a workhorse of prototyping, praised for its accessibility and straightforward process. Yet, SLA counters with a swish of resolution and aesthetics. Here’s the tale of the tape:

- Quality and Precision: SLA, with its intricate laser dances, etches out victory with layers so fine that the naked eye marvels at the detail. FDM, while sturdy, often succumbs to the might of visible layer lines.

- Material Differences: FDM’s thermoplastic filament boasts a variety of properties, but the resins of SLA shine with a spectrum broad and vibrant, offering specializations that FDM can’t easily mimic.

- Speed and Cost: FDM typically leads with swiftness and a gentle tug on the purse strings, making it a champion for the economical and the efficient. SLA, though not lagging too far behind in speed, does demand a premium for its splendid detail.

SLA vs. SLS: The Tussle of Refinement and Durability

Now, enter SLS, the dauntless gladiator, wielding a laser sintering powder into formidable and durable objects. SLA meets its gaze with the calm of an artisan. Here’s their measured contest:

- Finish and Details: SLA stands unchallenged in its domain of smooth surfaces and crisp features. SLS, though robust, often presents a sandy, grainy finish to the touch.

- Structural Integrity: SLS-built objects are renowned for their functional strength, enduring stress with a stoic resolve. SLA, while structurally sound, often defers to SLS in the arena of functional toughness.

- Support Structures: SLA’s need for supports can be a hamartia, a tragic flaw, in the face of SLS’s self-supporting prowess—no structures to remove, no marks to polish.

The Dichotomy of Choice: A Controversial Crossroads

Within these comparisons lurks the subtle art of decision-making – a choice that has sparked many a debate in the workshops of creators:

- The Decision of Detail: Opt for SLA when the prototype’s intricacy and finish are the sirens of your venture.

- The Play of Strength: Embrace SLS or FDM when the path demands endurance and the might to withstand the trials of function and form.

- The Game of Costs: If the purse strings are tight, and the vision allows, FDM can be the champion you seek.

Confronted with the task of choosing a champion, the wise weigh their options with care. In the grand scheme, SLA, FDM, and SLS each carve their niche—SLA with the grace of minute detail, FDM with the breadth of accessibility and economy, and SLS with the might of durability and autonomy.

To summarize, in this triumvirate of technology, the choice hinges on the nature of the prototype, the depth of one’s coffers, and the tale one wishes to tell. SLA, with its razor-sharp acuity and mirror-like finish, offers a resounding answer to the call for intricacy and artistry. Yet, the contemplative creator pauses and ponders, for the right choice is a tapestry woven from the many threads of project needs.

Limitations and Challenges of SLA 3D Printing: The Hurdles of High Precision

Amidst the fanfare extolling the virtues of SLA 3D printing, it’s crucial to navigate the waters of reality, which are not always calm. Even as SLA stands as a paragon of precision in rapid prototyping, it faces its own set of limitations and challenges. The path of innovation is not devoid of hurdles, and understanding these is key to harnessing SLA’s full potential.

Tackling the Costs: The Economic Equation

Investment and Operational Costs: SLA 3D printers often come with a hefty price tag, accompanied by higher operational expenses. The resins can be luxurious sirens, calling with the promise of quality but demanding their due in cost.

Delving into Durability: Material Matters

Material Limitations: While SLA resins can capture detail exquisitely, they often do not match the mechanical and thermal performance of their FDM and SLS counterparts, leading to concerns about the durability and lifespan of SLA prints.

Contemplating the Constraints: Size and Scale

Build Volume Restrictions: SLA printers typically offer a smaller build volume compared to FDM and SLS machines, making SLA less suited for large-scale prototypes or production runs, creating a bottleneck for scalability.

Post-Processing: The Double-Edged Sword

Post-Processing Requirements: The necessity of washing and curing SLA prints adds additional steps to the creation process. While these steps ensure a pristine finish, they also contribute additional time and labor.

Navigating the Post-Processing of SLA Prints: The Final Frontier of Fabrication

Harnessing the power of SLA 3D printing places us at the precipice of fabrication innovation, but the journey doesn’t end as the printer’s light dims. The final act – post-processing – commences once the print is born, a phase as crucial as any that came before. This stage is where the true finesse of a print is unearthed, refined, and brought to its full luster.

The Cleansing Rites: From Rinse to Refinement

Washing: Fresh from the resin bath, SLA prints emerge clad in uncured resin. The first pilgrimage is to the wash station, where an alcohol or solvent bath awaits to purify the print, stripping away excess resin.

Post-Curing: Post-washing, the print undergoes a rite of passage under UV light. This curing process solidifies the resin, enhancing the print’s strength and stability.

Support Removal: A Delicate Severance

Delicate Extraction: SLA prints often require support structures that must be meticulously removed. This is a surgeon’s task, precise and calculated, for each unwanted support is a blemish waiting to mar the surface if not carefully excised.

Sanding and Polishing: The Art of the Surface

Sanding: To achieve the iconic smoothness SLA is renowned for, the prints may undergo a painstaking process of sanding, from coarse to fine grits, each pass bringing the surface closer to perfection.

Polishing: For those seeking a reflective sheen, a stage of polishing may follow sanding. Buffing compounds and cloths dance over the print’s surface, imbuing it with a shine that rivals the gloss of injection-molded parts.

Painting and Finishing: The Chromatic Touch

Painting: With a smooth surface as a canvas, painting can imbue an SLA print with vibrant life, fully realizing the creator’s vision in color.

Finishing Touches: From metallic coatings to hydro dipping, the realm of finishing techniques is limited only by imagination, each adding a final statement to the piece.

Addressing the Elephant in the Room: Challenges and Controversies

The path of post-processing is not without its pitfalls:

- Time and Labor Intensity: Each step in the post-processing phase can be labor-intensive, demanding both time and skill, which in turn can lead to increased costs.

- Environmental Concerns: The use of solvents and disposal of uncured resin raise environmental concerns, calling for conscious practices and proper waste management.

Navigating the Balancing Act: In the grand calculation, the decision to invest in the post-processing of SLA prints is often a balance between the desire for quality and the realities of time, cost, and environmental impact.

The crux of the dialogue surrounding SLA post-processing is not whether the steps are necessary, but how they are carried out and to what extent. Cutting corners may save time and money, but at the cost of diminishing the print’s inherent potential. Conversely, devoting too much to post-processing can be uneconomical.

The ethos of SLA post-processing is thus one of striking a harmonious balance. It’s about finding the middle ground where the final product reflects the meticulous care of its creation without resulting in excessive labor or waste.

In conclusion, post-processing is a testament to SLA’s capability to deliver unparalleled quality in 3D printing. It stands as both the final hurdle and the crowning step in the realization of a vision from liquid resin to a solid, tactile form. Herein lies the essence of craftsmanship, where patience, attention to detail, and respect for the material converge to unveil the final masterpiece of SLA 3D printing.

Future Developments: The Evolving Landscape of SLA 3D Printing

The domain of SLA 3D printing is far from static. It is pulsing, alive with the promise of innovation, poised on the cusp of tomorrow. As we gaze into the horizon, the landscape of SLA printing is evolving, driven by relentless advancement and the unyielding quest for perfection. Let’s illuminate the frontiers pushing SLA into the future, promising to transcend today’s limitations and unfold new possibilities.

3D Printing Automation: The Inception of a Workflow Revolution

Automated Post-Processing: Innovations aim to streamline the labor-intensive post-processing phase, with machines dedicated to washing, curing, and even support removal, heralding a new era of efficiency.

Integrated Systems: The future envisions a seamless workflow where SLA printers are part of an integrated system, automatically moving prints through each post-processing stage, reducing touchpoints, and minimizing human error.

Speed Improvements: Racing Against Time

Faster Printing Techniques: Groundbreaking SLA technologies like continuous liquid interface production (CLIP) are dramatically increasing the speed of 3D printing, pushing the boundaries of what can be done in a given time frame.

Parallel Processing: Multi-laser systems and advanced scanning strategies are also anticipated to speed up the SLA printing process, enabling the simultaneous creation of multiple parts.

Accessibility and Affordability: Democratizing Innovation

Cost Reduction: As SLA technology matures, the costs of machines and materials are expected to decrease, making SLA 3D printing more accessible to hobbyists, small businesses, and educational institutions.

Open Source Movement: There is a burgeoning community committed to open-source SLA hardware and resin formulations, which is likely to further drive down costs and catalyze innovation.

The Controversy of Expansion: Quality vs. Quantity

The path forward for SLA is not free from debate. As the technology becomes faster and more accessible, will the unparalleled quality that defined SLA be maintained, or will it give way to a new standard?

Navigating Growth: The core controversy centers on balancing growth with maintaining the high-resolution, surface finish, and intricate detail that SLA is prized for. How the community navigates this balance will shape the trajectory of SLA’s future developments.

SLA is advancing at an unprecedented pace, and with each breakthrough, it reshapes the narrative of what is possible. From the chemistry of resins to the very processes that define SLA printing, innovation permeates every facet.

In conclusion, the future of SLA 3D printing is one of great potential and promise. It strides boldly into uncharted territories, aiming to not only enhance the capabilities of prototyping and production but also to shift the paradigm of manufacturing itself. As enthusiasts, professionals, and visionaries alike watch this evolution, there’s a shared anticipation for a future that is more efficient, more accessible, and more spectacular in what can be achieved with the simple yet sublime power of light and resin.