Do you ever wonder how 3D printing works? If so, you’re not alone. One of the most advanced forms of 3D printing technology is selective laser sintering (SLS). SLS is a revolutionary technology that allows you to create complex 3D models with incredible precision and accuracy. In this article, we’ll take a deep dive into SLS, exploring how it works, its applications, and its benefits.

What is Selective Laser Sintering (SLS)?

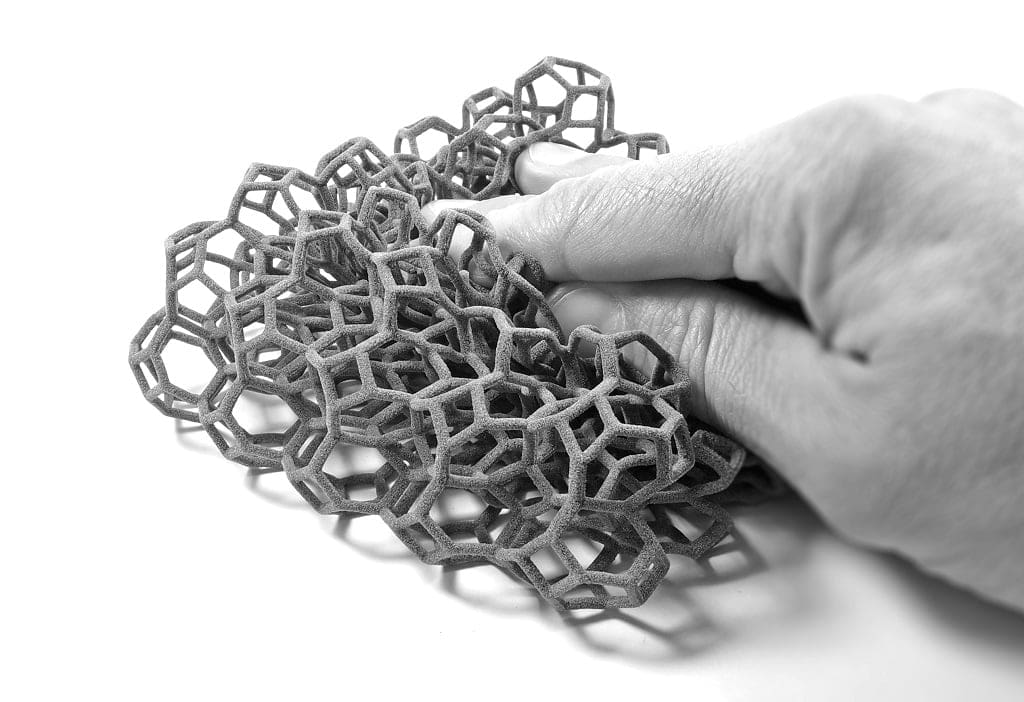

SLS is a 3D printing technology that uses a laser to selectively fuse small particles of plastic, metal, or ceramic powder together to form a solid 3D object. The process involves the use of a high-powered laser that melts and fuses the powdered material together, layer by layer, until the final object is created.

How Does SLS Work?

SLS involves three key steps:

- Material Preparation: The material used in SLS is typically a fine powder that is loaded into the printer’s hopper. The powder is then spread evenly onto a build platform.

- Laser Scanning: The printer’s laser then scans the surface of the powder, selectively melting and fusing together the particles to create a solid layer.

- Layer-by-Layer Construction: Once the first layer is complete, the build platform lowers slightly, and the process repeats, layer by layer, until the final object is complete.

Applications of SLS

SLS is used in a variety of industries, including aerospace, automotive, and healthcare. Some of the most common applications of SLS include:

- Prototyping: SLS is an excellent technology for creating prototypes due to its ability to produce highly detailed and accurate models quickly and easily.

- Manufacturing: SLS can be used for short-run manufacturing, as it is more cost-effective than traditional manufacturing methods.

- Art and Design: SLS can be used to create complex, one-of-a-kind art and design pieces that would be difficult or impossible to produce with traditional manufacturing methods.

Benefits of SLS

SLS offers a range of benefits, including:

- High Precision: SLS can produce highly detailed and accurate models with tight tolerances.

- Material Variety: SLS can work with a variety of materials, including plastics, metals, and ceramics.

- Cost-Effective: SLS is often more cost-effective than traditional manufacturing methods, especially for short-run production.

Selective laser sintering (SLS) is a revolutionary 3D printing technology that has transformed the way we think about manufacturing, prototyping, and design. With its ability to produce highly detailed and accurate models quickly and easily, SLS has become a go-to technology for a wide range of industries. If you’re looking to create a prototype or produce a small run of parts, SLS may be the perfect solution for you.