Selective Laser Melting

SLM 3D Printer

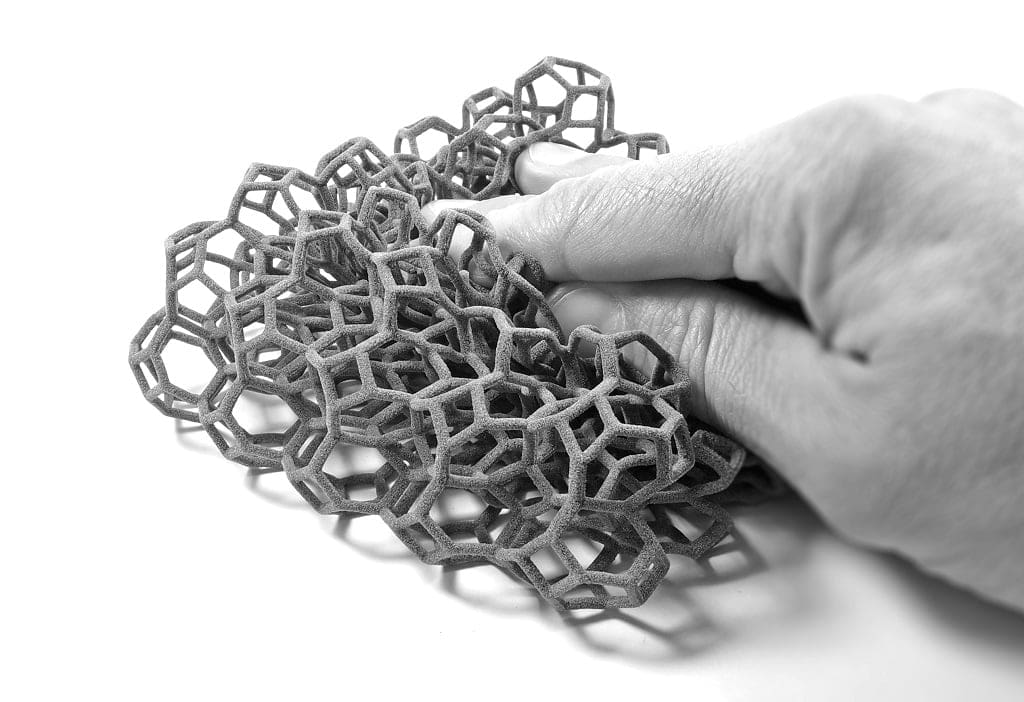

Metal Additive Manufacturing for Creative Development

Efficient cost reduction

Maximize Printing Efficiency with our Optimized Gas Flow Design: Say Goodbye to Smoke, Splashes and Inconsistent Results!

High quality molding

Revolutionize Your 3D Printing with Dynamic Software that Allows Precise Control of Model Sections: Achieve High-Quality Finished Parts by Tailoring Process Parameters to Upper Surfaces, Core Areas, Small Parts, and More!

High precision Printing

Enhance Your Precision 3D Printing with Dual Laser Technology: Achieve ≤±0.1 mm Overlapping Deviation and Preserve Mechanical Integrity for Parts Comparable to Those Printed on Single Laser Machines!

mass production

Move Beyond Limitations with Our Superior 3D Printing System: Closed-Loop Powder Handling, and Upgraded Process Control for Maximum Productivity and Performance in High-Demand Applications!

SLM 300 Production Series

Take Your Additive Manufacturing to the Next Level with Our High-Power, Multi-Laser SLM 300 Production Series: Featuring a 25 Larger Build Plate for Increased Part Output and Our Patented Multi-Laser Scan Strategy to Minimize Soot Interference and Deliver Uncompromising Density and Mechanical Properties!

| Build Volume | No less than 140mm140mm100mm | Laser Power | 300W/500W Optional |

| Coating Method | Up power, two-way powder | Z axis Resolution | 1MM |

| Equipment Power | 5KW | Galvanometer Type | Scanlab high speed digital galvanometer |

| Power Supply | 380V NPE | Circulatory Sytem | 0-2.5m³/Min,Air curtain protection |

| Laser Type | Fibre Laser 1064nm | Filter System | >0.5μm particle filtration efficiency 99.9% |

| Beam Diameter | 50~80μm | Preheating Temperature | 200°C |

| Scanning Speed | 0-7M/S | Scanning Method | Both lasers printed independently or in combination |

| Gas Protection | Argon,nitrogen 3.5L/min | Control Software | FastFab,level control,process guidance and online monitoring |

| Scanning Accuracy | Size error of ±0.1mm for all dimension Within 100mm above 100mm is ±0.1% | Processing Software | Fastlayer,Support STL model processing,model layout and transformation,automatic model repairment |

| Printable Material | Stainless steel,titanium alloy, die steel,cobalt chromium alloy,aluminum alloy and other metal materials | Slice Software | Fastlayer,Support thickness 0.02-0.1mm,material parameters library,multiple scanning method selection |

More Product Details