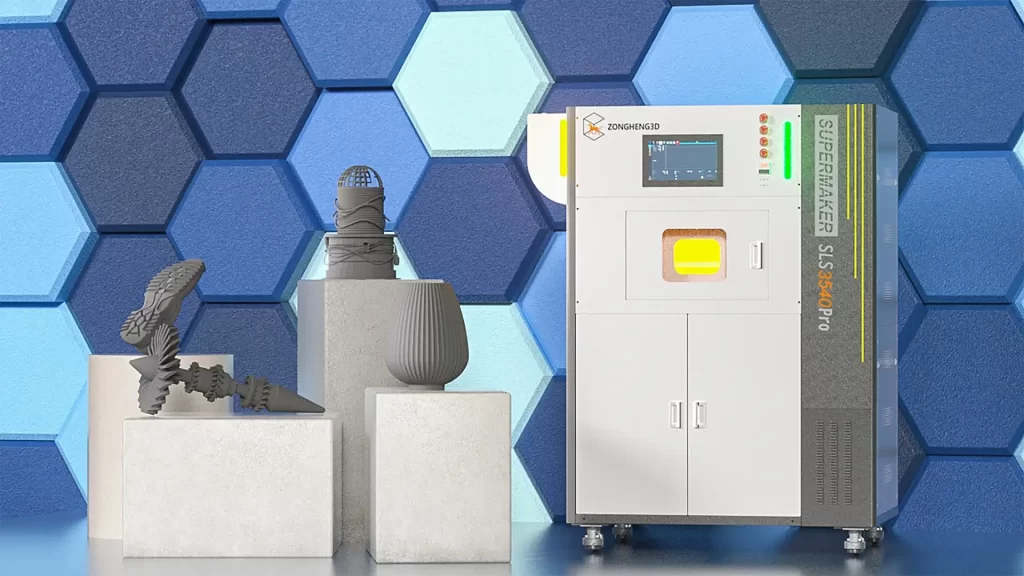

The new SLS-3540 PRO selective laser sintering 3D printer represents a revolutionary leap forward for industrial additive manufacturing, enabling unprecedented capabilities for high precision, complex geometries, accelerated workflows, and distributed production.

As a leading pioneer in professional 3D printing solutions, we are thrilled to officially launch the SLS-3540 PRO – our most advanced SLS printer yet engineered for precision, efficiency, and design freedom.

This innovative system unlocks transformative potential for organizations to digitize manufacturing and streamline everything from rapid prototyping to end-use production.

Achieve Extraordinary Precision Down to 0.07mm Layer Resolution

At the core of the SLS-3540 PRO is a [high-precision German laser] capable of remarkable 0.07mm resolution, allowing creation of extremely intricate and complex part geometries impossible with traditional subtractive techniques.

The specialized [path planning algorithms] and [process controls] take full advantage of the laser’s capabilities for pinpoint accuracy. This enables precise control over the entire sintering process right down to the micron level.

With the SLS-3540 PRO, businesses can now manufacture detailed components with fine features for applications from “industrial equipment” to “consumer products”. The printer’s exceptional precision empowers your organization to achieve new heights of manufacturing excellence.

Maximize Design Freedom with the Largest Build Volume in Its Class

The SLS-3540 PRO offers the [largest build volume of 350 x 350 x 430 mm] in its class, providing expanded capability to produce larger or multiple parts in a single print run.

This massive space combined with the lack of support structures gives engineers unprecedented freedom to optimize designs for weight reduction, performance gains or customization.

Complex enclosed assemblies such as hydraulic manifolds and integrated electronics housings can be printed as a single part, consolidating sub-components. Lightweighting or topology optimization of items like [automotive brackets] and [aircraft ducting] is also made far simpler.

The immense design freedom of the SLS-3540 PRO facilitates rapid iteration to create enhanced products perfectly suited for your applications.

Print Real Engineering Thermoplastics for Durable End-Use Parts

The SLS-3540 PRO utilizes ‘high-performance materials’ like nylon and glass-filled nylon specifically formulated for laser sintering processes. Parts printed from these engineering thermoplastics possess exceptional mechanical properties.

The printed components can withstand prolonged use in demanding industrial environments, with heat and chemical resistance exceeding metals in many cases. This enables direct manufacture of durable end products for the automotive, aerospace, appliance, consumer goods, and healthcare sectors.

By using real engineering materials instead of prototyping plastics, your organization can deploy finished goods right off the printer. The SLS-3540 PRO merges design with production to truly digitize manufacturing.

Streamline Workflows with Automated Production and 100% Powder Reuse

The SLS-3540 PRO features an ‘automated production system’ to maximize productivity and consistency while minimizing labor costs. Every step from unpacking to depowdering is engineered to be hands-free.

The printer also delivers ‘near 100% material utilization’ by reusing excess powder for future builds. This saves tremendously on material costs, especially for small to medium production runs. Combined with the lack of tooling, the SLS-3540 PRO provides a very compelling return on investment.

The hassle-free operation and material reuse capabilities helps your team focus on innovating instead of production logistics. Manufacturing is simplified and more responsive to shifts in market demand.

Accelerate Time-to-Market with Rapid Prototyping and Validation

The SLS-3540 PRO is engineered for **maximum speed and throughput** to help compress development timelines and get products to market faster.

The high-performance laser and optimized scanning algorithms deliver class-leading print speeds up to **25 times faster** than competitor systems. Parts are also ready to use directly off the machine with no post-processing.

Engineers can iterate through multiple design prototypes in just days instead of waiting weeks. Functional performance and durability can be validated rapidly well before committing to tooling. This enables early-stage design refinement to maximize product quality and commercial success.

The blindingly fast print speeds combined with real engineering materials makes the SLS-3540 PRO the ideal solution for accelerated product development.

Distributed Manufacturing Capabilities with a Small Footprint

The SLS-3540 PRO packs its formidable capabilities into a **surprisingly compact footprint** of just 1.35 x 0.95 x 1.9 meters. This allows installation in space-constrained facilities closer to local markets and end-users.

Spare office or warehouse space is all you need to set up localized production. Inventory and transportation costs are slashed while order fulfillment lead times shrink from weeks to days.

The distributed manufacturing model enabled by the SLS-3540 PRO provides tremendous flexibility to relocate and reconfigure production in response to changing demands. Manufacturing is no longer locked into fixed facilities and rigid assembly lines.

Unleash Your Team’s Potential with Breakthrough Additive Manufacturing

The SLS-3540 PRO delivers unprecedented performance, efficiency, and adaptability that redefines expectations of industrial 3D printing. This innovative system expands your organization’s capabilities and opens up a new world of possibilities:

– Manufacture highly complex geometries impossible with machining

– Engineer optimized lightweight structures for improved performance

– Produce durable end-use parts ready for the most punishing conditions

– Streamline and digitize workflows from design through production

– Accelerate innovation and reduce product development timelines

– Establish localized production that is flexible and responsive