3D printing has revolutionized the way we create and manufacture objects, and it’s no wonder that more and more people are curious about it. One question that often arises is: What is the difference between SLA and SLS 3D printing? In this comprehensive guide, we will delve into the world of 3D printing technologies, specifically focusing on Stereolithography (SLA) and Selective Laser Sintering (SLS). We’ll explore their similarities, differences, applications, and which one might be best suited for your needs. So, let’s dive right in!

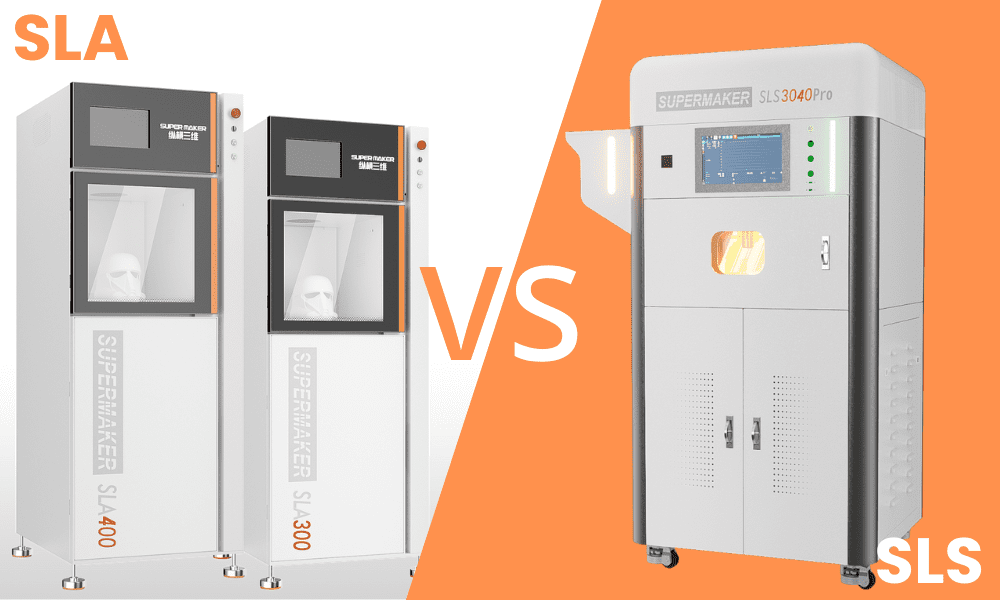

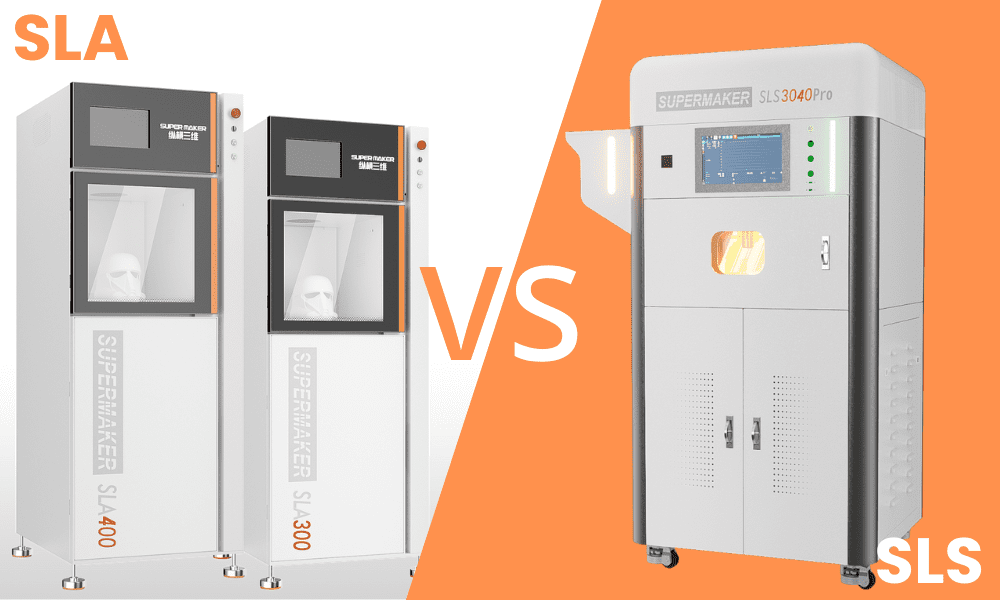

SLA vs. SLS: Tale of Two Technologies

What is SLA 3D Printing?

SLA, or Stereolithography, is a 3D printing technology that uses a UV laser to cure liquid resin into solid objects. The process involves directing a laser beam onto the surface of a vat of photopolymer resin. As the laser moves across the resin, it hardens the material layer by layer, eventually forming a complete 3D object.

Pros of SLA 3D Printing

- High resolution and accuracy

- Smooth surface finish

- Ability to create intricate details

Cons of SLA 3D Printing

- Limited material options

- Requires post-processing

- Not as suitable for large-scale production(just for consumer level machine)

What is SLS 3D Printing?

SLS, or Selective Laser Sintering, is another popular 3D printing technology that uses a high-powered laser to fuse powdered material (typically nylon or other thermoplastics) into solid objects. The laser selectively sinters the powder particles together, layer by layer, until the desired shape is achieved.

Pros of SLS 3D Printing

- Wide range of material options

- Durable and functional parts

- No support structures needed

Cons of SLS 3D Printing

- Rougher surface finish

- Longer production times

- Higher costs for small-scale projects

Comparing SLA and SLS: Which One is Right for You?

SLA

SLS

Applications

SLA is particularly well-suited for:

- Prototyping

- Jewelry and dental applications

- Miniatures and models

- Artistic projects

SLS, on the other hand, is ideal for:

- Functional parts and prototypes

- Automotive and aerospace components

- Medical devices

- Customized products

Cost and Production Time

SLA tends to be more cost-effective for small-scale projects due to its lower material costs. However, SLS may be more economical for larger production runs because it can produce multiple parts simultaneously.

In terms of production time, SLA usually offers faster turnaround times for individual items. However, SLS can produce multiple parts at once, potentially reducing overall production time for larger orders.

Frequently Asked Questions

- Q:Can I use both SLA and SLS for my project?

A:Absolutely! Depending on your project requirements, you may find that combining both technologies can provide the best results. - Q:Which 3D printing technology offers better quality?

A:SLA typically produces higher-resolution prints with smoother surface finishes. However, SLS can create more durable and functional parts. - Q:Are there any other 3D printing technologies I should consider?

A:Yes! There are many other 3D printing technologies available, such as Fused Deposition Modeling (FDM), Digital Light Processing (DLP), and Multi Jet Fusion (MJF). Each technology has its own advantages and drawbacks, so it’s essential to research which one is best suited for your project.

In a nutshell, the main difference between SLA and SLS 3D printing lies in the materials used and the method in which they are processed. SLA offers high-resolution prints with smooth finishes, making it ideal for intricate designs and prototypes. On the other hand, SLS provides durable and functional parts suitable for various industries and applications.

Ultimately, the choice between SLA and SLS will depend on your specific project requirements, budget, and desired outcomes. By understanding the key differences between these two technologies, you can make an informed decision to bring your ideas to life in the most efficient and effective way possible. Happy printing!