The Complex Web of SLA 3D Printing Challenges

Stereolithography (SLA) 3D printing may seem like alchemy—transforming liquid resin into solid objects with precision and ease. But even alchemists face their share of adversities. Here, we will unravel the intricate challenges that persist within the realm of SLA 3D printing, casting light on the problems that artisans and engineers frequently grapple with. Let’s dive into the rich tapestry of issues that this modern-day sorcery encounters.

Material Issues: The Silent Gatekeepers of Quality

The choice of resin in SLA 3D printing is like selecting the finest ink; it can profoundly impact the final masterpiece. However, users encounter a range of material-centric hurdles:

- Limited Range of Materials: Unlike FDM (Fused Deposition Modelling) printers that can print with a variety of plastics, SLA printers are typically confined to specific resins, restricting creative and functional choices.

- Cost of Resins: The specialized nature of SLA resins comes with a steep price tag, a barrier for those exploring the technology on a budget.

- Resin Storage and Handling: The longevity and quality of resins are contingent on proper storage. Exposure to sunlight or even ambient UV light can prematurely cure the material, while suboptimal storage temperatures can alter viscosity, affecting print quality.

Resin Type Properties Ideal Use Case ———– ———– —————– Standard Balanced detail and strength General Prototyping Tough High strength and durability Functional Parts Flexible Simulates rubber-like properties Ergonomic Prototypes Castable Burns out without residue Jewelry and Dental## **Machine-Related Challenges**: The Titans of Technicality

An SLA printer might look like a sleek monolith of innovation, but beneath the surface, there are mechanical complexities at play.

- Initial Setup Complexity: Dialing in the printer settings can be an intricate dance that often dissuades newcomers. Setting Z-axis height, laser power, and other parameters require patience and precision.

- Calibration Difficulties: Regular calibration is non-negotiable to ensure accuracy. However, the process can be daunting, and neglect leads to diminished part quality.

- Long-Term Maintenance: SLA printers demand meticulous upkeep. The laser’s path must be clear, the resin tank clean, and the build plate level—tasks that accumulate to form a towering wall of maintenance chores.

Design Constraints: The Invisible Walls of Innovation

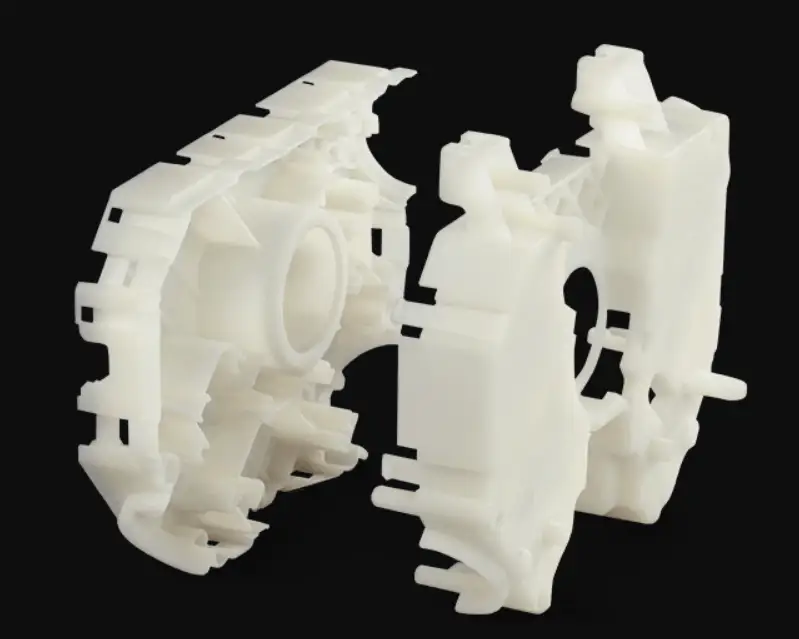

In SLA 3D printing, the design’s complexity isn’t merely a measure of one’s imagination—it’s a puzzle, demanding conformity to technology limitations.

- Limitations in Size and Shape: The restricted build volume of many SLA printers confines the ambition of larger projects, often requiring them to be pieced together like a 3D jigsaw puzzle.

- Support Structure Complexities: Overhangs and bridges need support structures that, while necessary, can lead to wastage of materials and additional post-processing.

- Layer Adhesion Problems: Each layer must perfectly adhere to the previous one, and any miscalibration can result in the dreaded delamination, peeling away the layers of your hard work.

Did You Know? SLA 3D printing is as much about the aftermath as it is about the printing process. Post-processing, grading, and curing are not just optional steps; they are essential rites of passage for every print to reach its zenith of quality.

With its delicate balance of precision, patience, and practice, SLA 3D printing remains a craft enveloped in technical mystique. But with awareness and a proactive approach to these endemic challenges, the path to consistent prints of the highest quality becomes navigable. As we examine each facet of these challenges, let’s remind ourselves that with every difficulty mastered, the craft only becomes more rewarding.

Quality and Precision Concerns in SLA 3D Printing

Precision is the promised land of SLA 3D printing, the pot of gold at the end of the rainbow. However, reaching it is not without traversing a path fraught with quality and precision concerns that could deter even the bravest of makers and creators. In this segment, we will dissect these concerns meticulously, much like how an SLA printer approaches each layer of a print— with precision and attention to the minutest detail.

The Fine Line of Accuracy and Precision

Resin Shrinkage and Deformation: The Changelings of 3D Printing

Post-curing shrinkage in SLA 3D printing is akin to cotton clothing—it seems to fit until you wash it for the first time.

- Curing Conundrum: As SLA prints cure, the resin tends to shrink slightly. This can lead to parts not fitting together as intended or details warping, a significant concern when precision is paramount. Understanding and anticipating this dimensional shift is crucial for any SLA practitioner.

- Temperature’s Tightrope: Temperature plays a significant role in how resin behaves. If your workshop fluctuates between the Sahara at noon and the Arctic at dawn, your prints will bear the brunt of these extremes. Consistent ambient temperatures mitigate unforeseen shrinkage or expansion.

Layer Thickness Limitations: The Double-Edged Sword of Detail

In SLA 3D printing, layer thickness can be both a blessing and a curse. Thinner layers mean higher resolution but also longer print times and increased potential for failure.

- Balancing Act: Choosing the ideal layer thickness is a balancing act between desired detail and practical feasibility. While thinner layers capture more detail, they can multiply print times and add to the potential for print failure.

- A Question of Strength: It’s not just about looks. Thicker layers can lend more strength to a print, a crucial factor in functional prototypes.

Post-Curing Induced Deformities: The Unwelcome Surprises Post-Creation

- UV Crosslinking: It’s about achieving the right crosslinks within the polymer matrix. Incomplete or uneven post-curing can lead to brittle prints or parts that are not truly ‘set’, reducing their functional lifespan.

- Cure Smart, Not Hard: Investing in a quality UV curing station that delivers even and measured exposure can make all the difference. Think of it as a spa for your prints—they come out rejuvenated and strong.

The Rough Road to a Smooth Surface Finish and Detail

Stair-Stepping Effect: The Unwanted Texture in a Smooth World

The stair-stepping effect in SLA printing is often like unwanted texture in a serene painting— it stands out.

- Layer by Layer: This effect surfaces when the layer height is too prominent compared to the object’s slope, revealing the individual layers. The solution is either to decrease layer height or to strategically orient the print to minimize the steps.

Post-Processing Requirements: The Necessary Aftercare

Turning a raw print into a tactile masterpiece requires post-processing—a necessary aftercare regime.

- Clean and Cure: Before you even begin sanding or painting, properly cleaning and curing your prints is foundational. This step solidifies your details and ensures your surface is ready for finishing touches.

- Sanding and Polishing: Careful sanding can help smooth out the stair-stepping, but it’s essential to do so with a gentle hand to avoid obliterating those crisp details that SLA is known for.

Expert Tip: Use progressively finer grits of sandpaper, and consider wet sanding for even smoother results.

Every SLA 3D printing endeavor is an exploration into the fragile balance between myriad factors that affect quality and precision. Understanding and mastering these concerns not only ensures each print’s success but also enriches the user with a deeper grasp of this craft. It’s in navigating through these minute yet significant hurdles that the true art of SLA 3D printing is realized—a testament to the pursuit of perfection in a world where detail is king.

Navigating Health and Safety Issues in SLA 3D Printing

In the meticulous world of SLA 3D printing, where technology meets craftsmanship, health and safety considerations often lurk in the background, eclipsed by the marvel of creation. Yet, they remain an indispensable aspect of the process that cannot be ignored. In this discursive journey, we shall lift the veil on the health and safety challenges associated with SLA 3D printing—illuminating the path with the glow of informed caution and care.

Toxicity of Materials: A Cautionary Tale

Handling and Disposing of Resins: The Perilous Liquids

SLA resins are the lifeblood of stereolithography. However, their chemical stability and reactivity are double-edged swords.

- Skin Contact: Direct skin contact with uncured resin can lead to irritation or allergic reactions. Thus, donning gloves becomes an essential ritual for the SLA artisan.

- Inhalation Hazards: Volatile organic compounds (VOCs) released during the printing and curing process are invisible foes that can affect air quality and respiratory health.

Safety Equipment Purpose ————— ——- Gloves Protect skin from irritation Respirator Masks Filter out harmful VOCs Safety Goggles Shield eyes from splashes### **Potential Health Risks**: The Unseen Enemies

The risks associated with the materials used in SLA printing extend beyond immediate physical contact.

- Long-Term Exposure: Chronic exposure to resin fumes and particles can pose long-term health risks, making ventilation systems and dedicated workspaces not a luxury, but a necessity.

- Resin Spills: Accidental spills need swift and proper cleanup with designated kits to prevent the resin from becoming a permanent, toxic stain in the environment.

Environmental Concerns

Disposal of Uncured Resin: The Responsible Finale

As the final curtain falls on an SLA print’s lifecycle, disposing of the uncured resin responsibly is crucial.

- Cured Resin: Fully cured resin is considered safer and can often be disposed of like regular waste. Still, local regulations reign supreme and must be consulted.

- Liquid Resin: Pouring liquid resin into the garbage—or worse, down the drain—is an ecological faux pas. Special disposal measures should be followed, often involving curing the leftover resin before disposal.

Ventilation and Exposure: The Invisible Mantle of Safety

- A Breath of Fresh Air: Effective ventilation removes airborne contaminants, keeping the air in your printing sanctum both clean and compliant.

- Segregation is Key: If possible, dedicate a room solely to printing, where the printer’s exhaust can be routed outside, away from common areas.

Closing Thoughts: Safety and Craftsmanship as Co-Artisans

In the delicate dance between creating with SLA 3D printing and maintaining a safe environment, one cannot exist without the other. It is a partnership where safety informs the quality of craftsmanship. By integrating comprehensive health and safety practices into our 3D printing routines, we do more than protect ourselves; we craft with respect towards our wellbeing and the environment.

Bearing in mind the potency of the materials and the significance of a health-conscious workflow, we pave the way for a sustainable future in 3D printing—a future where innovation continues to thrive, but not at the cost of our health or the planet. In adhering to these principles, we elevate our craft, ensuring that with every print, we are not just creating art or utility, but also honoring the ethos of responsible creativity.